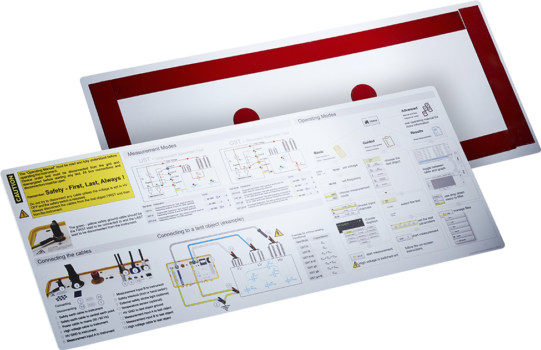

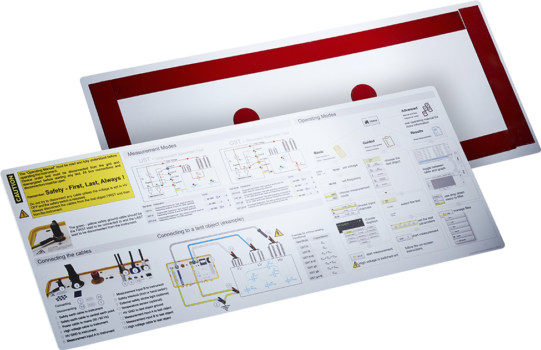

Flow & orientation diagrams

- Versatile application

- Maintaining the safety standard

- Milling, drilling, stamping

Our complete service: Advice, draft, final artwork, typesetting, film production and support afterwards.

Service Prices of semi-finished productsKünkler Industrieschilder

GmbH & Co. KG

Tuchbleiche 1

57648 Unnau/Germany

Fon: +49 (0)2661 95 51 0