Stainless steel

- Stainless steel V2A (1.4301)

- Thickness 0.5 mm surface glossy

- Thickness 0.8 to 2.0 mm surface grain 240

- Stainless steel V4A (1.4571)

- Thickness 0.8 to 2.0 mm

- Surface grain 240

Aluminium

- Aluminum AlMg 3 / H22

- Thickness 0.5 to 15 mm

- Raw, bright rolled

- Silver C-0 satin anodized

- Black C-35 satin anodized

- Brown C-34 satin anodized

- Bronze C-31 / C32 / C-33 satin anodized

- Silver C-0 UVD (uncompacted) satin anodized

- Aluminum composite panels (Dibond)

- Thickness 2 to 4 mm

- White on both sides, core black

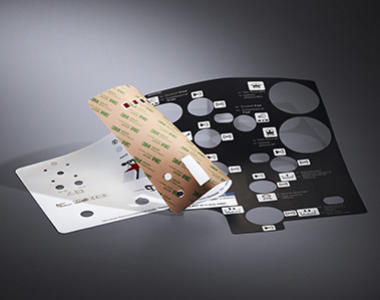

Plastic

- Acrylic glass GS transparent

- Thickness 1 to 10 mm

- PVC hard

- Thickness 0.8 to 12 mm

- white or grey

- plotter foils

- Oracle 751C

- Thickness 0.06mm

- Different colors

- Kömacel rigid foam

- Thickness 5 + 10 mm

- Color white

- Engraving materials 2-layer

- ABS material

- Different colors

- Thickness 0.8 to 2.0 mm

- Engraving materials 3-layer

- PVC material

- Different colors

- Thickness 0.8 to 2.0 mm

- Polyester films (PES)

- Matted front, smooth back

- Front / back transparent smooth (touch panel suitable)

- Thickness 0.15 / 0.20 / 0.25 mm

- Suitable for digital printing and screen printing

- Clear coat possible on the front

- Formica / melamine

- Different colors

- Thickness 0.8 to 3.0 mm

- Polycarbonate foils (PC-Lexan)

- Matted front, smooth back

- Thickness 0.25 / 0.375 / 0.5 mm

- Silk screen printing process only

If you have question we will be happy to help!

All contact persons

Andreas Altenburg

Managing Director

Phone: +49 (0)2661 95 51 25

Mail: info@schilder-kuenkler.de