Material

Plastic

Material

Plastic

Important plastics characteristics are their technical properties, such as mouldability, hardness, elasticity, breaking strength, temperature and heat resistance and chemical resistance.

Resistance, which can be varied within wide limits by selecting the macromolecules, manufacturing processes and usually by adding additives. Plastics are divided into three major groups in accordance with their physical properties: Thermoplastics, duroplastics and elastomers.

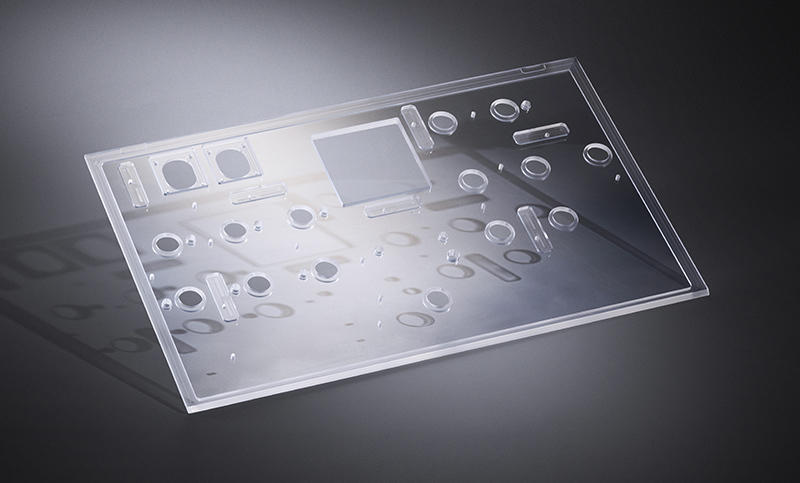

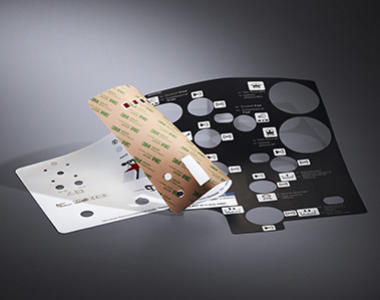

Plastics are further processed into moulded parts, semi-finished products, fibres or films. They are used as packaging materials, textile fibres, thermal insulation, pipes, floor coverings, components of paints, adhesives and cosmetics, in electrical engineering as material for insulation, circuit boards, housings, in vehicle construction as material for tyres, upholstery, dashboards, petrol tanks and much more.

The respective macromolecules in a plastic are polymers and therefore composed of repeating basic units. The size of the polymer macromolecules varies from a few thousand to over a million basic units. For example, the polymer polypropylene (abbreviation PP) consists of multiple repeating propylene units. The polymers can be unbranched, branched or cross-linked molecules.

The polymers can be derived from natural substances or purely synthetic. Synthetic polymers are produced by chain polymerisation, polyaddition or polycondensation from monomers or prepolymers. Semi-synthetic plastics result from the modification of natural polymers (mainly cellulose to celluloid), while other bio-based plastics such as polylactic acid or polyhydroxybutyric acid are produced by the fermentation of sugar or starch.

As the field of plastics is very wide we will leave it at the examples above.